High-End Precision Manufacturing Industry-3D Printing Application Case

Publish Time: 2025-04-25

System solution:

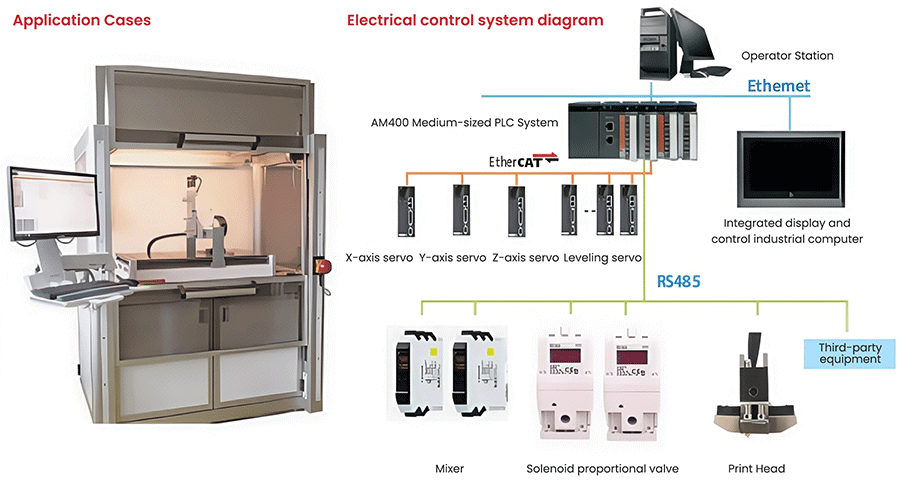

■ The 3D slicing software on the integrated display and control industrial computer slices the printed workpiece, generates the printing trajectory G code program, and sends it to the PLC through the Ethernet interface.

■ The main PLC uses a medium-sized PLC based on the Codesys system architecture, which supports CNC subroutines internally. The G code program can be sent through the host computer interface through the Ethernet interface, USB interface, etc. The theme architecture of the equipment control is built by the PLC program.

■ The trajectory feed axis is connected to the high-performance servo system by the PLC through the high-speed EtherCAT bus to perform three-dimensional axial feed control and printing platform leveling control.

■ The PLC connects two temperature controllers through the RS485 interface to control the temperature of the print head and the platform respectively. At the same time, according to the different printing materials, it also realizes the control of the electromagnetic proportional valve and the status monitoring of the print head.

System advantages:

System advantages:

■ The control system adopts a domestically produced high-performance medium-sized PLC system with powerful functions and reliable performance, and is not restricted by the supply chain of foreign manufacturers.

■ The system is completely independently developed, and subsequent maintenance and upgrades are convenient and fast.

■ The system has high printing accuracy and is suitable for high-precision small-size workpiece printing.